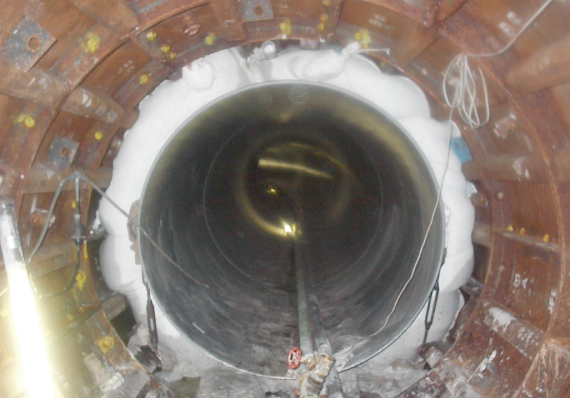

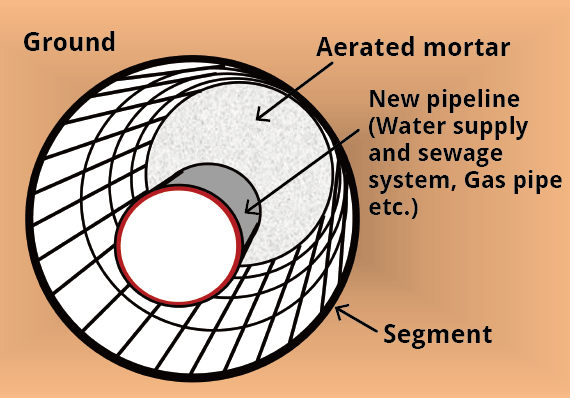

In a shield tunnel or a mountain tunnel, secondary lining of newly-built pipes is executed using Aerated mortar to prevent ground settlement and deformation of buried pipes. Also, pipelines are filled with Aerated mortar in order to stabilize and protect pipes. Aerated mortar is adopted for various pipes installation due to its excellent features such as lightweight, fluidity, cost effect and long-distance pumping.

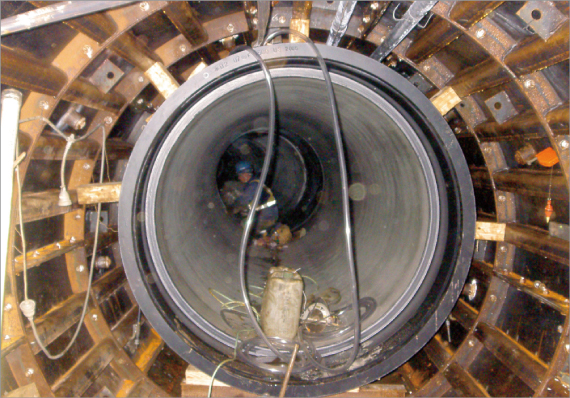

FW pipe, which is the reinforced plastic composite pipe i.e. FRPM pipe utilized in sewer on sewerage secondary lining site, is carried and installed in the segment, and grouting agent (Aerated mortar) is injected into the gap between the pipe and the segment in the secondary lining. It is lightweight, is easy to handle, enables shorter work period, and has high durability. After the lining works, prevention works for water leakage and other maintenance works are not necessary. Inner surface of FRPM pipe is smooth having low roughness coefficient (concrete: 0.013, FRPM pipe: 0.01) that enables its inner diameter of 10% less than the secondary lining of concrete, it delivers an economical way and high level of safety.